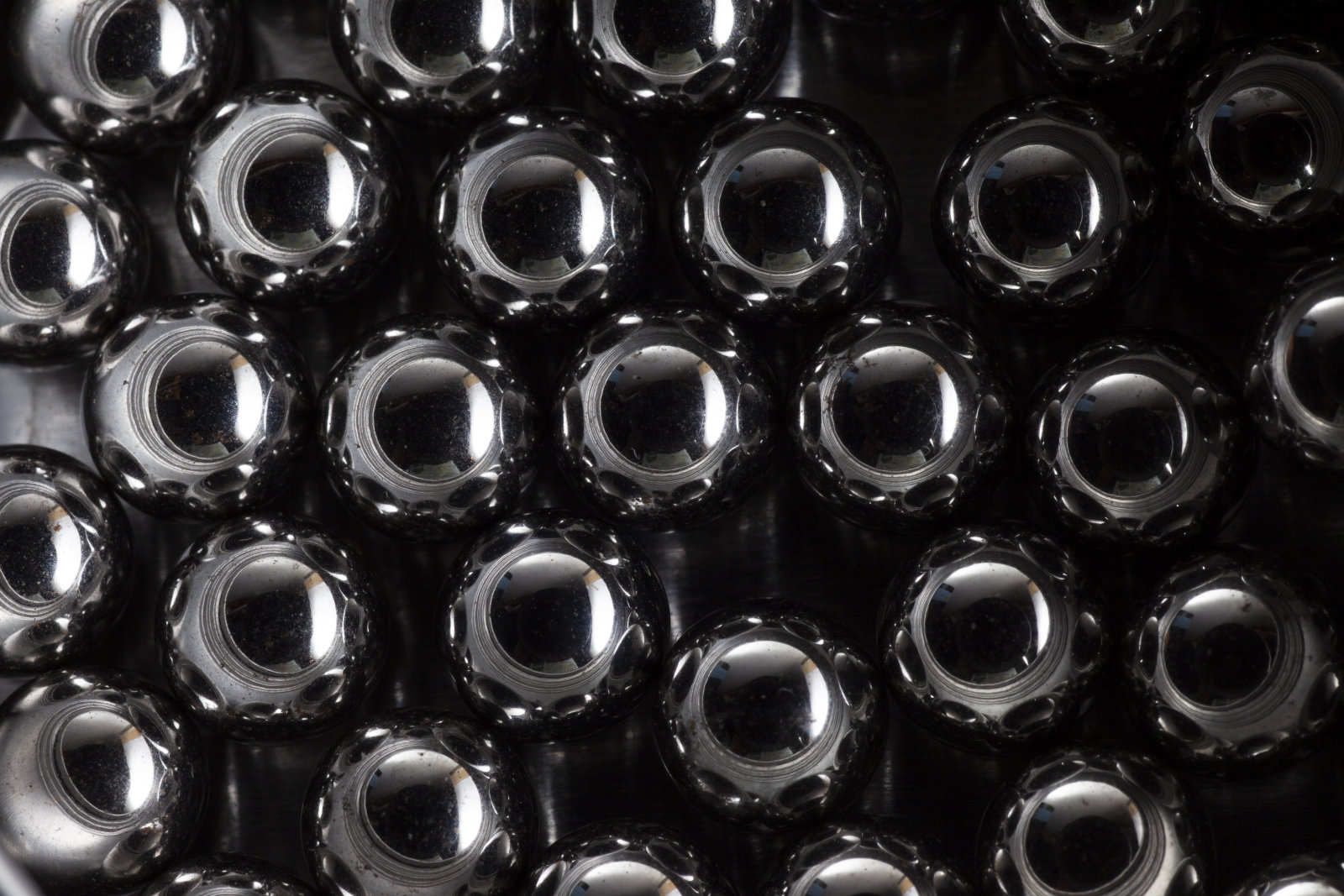

Reasons for poor surface roughness of steel balls

1. The processing volume is small and the

processing time is short.

2. The groove of the grinding disc is

shallow, and the contact surface between the groove and the workpiece is small.

3. The hardness of the grinding disc is too

high or uneven, and maybe there are trachoma and pores.

4. The added amount of abrasive paste is

too much, or the particle size of the abrasive is too coarse.

5. The groove of the grinding disc is too

dirty (there are iron filings or other debris).

The reasons for the poor local surface

roughness are: the groove of the rotating grinding disc is too shallow, and the

contact area of the workpiece is too small; the angle of the groove of the

grinding disc is too small, making the rotation of the workpiece inflexible;

the pressure applied by the upper grinding disc is too small, making Slippage

occurs between the workpiece and the grinding disc.